Kamen Buffer tanks

The buffer reduces the frequency of boiler activation, and thus increases the efficiency and durability of the installation, and protects it against overheating.

Buffer tanks are used to store excess heat, and when it is needed to transfer it to the heating system. Kamen produces steel storage tanks up to 200 l. designed to store heat from various sources such as a pellet boiler and solar panels. The tanks can be equipped with a steel or copper coil, operating simultaneously with equipment in open and closed systems, the maximum pressure is 0.3 MPa.

Features and benefits of Kamen storage tanks

KAMEN storage tank is easy to install and economical to use, it maintains the temperature of the heating system when the heat sources are switched off.

High performance and durability of the installation

– increases the durability of the installation – reduces the frequency of boiler starts

– protects devices from overheating

– stores excess energy and uses it when needed

REDUCTION OF HEATING COSTS and higher PROFITABILITY OF INVESTMENTS

Easy and cheap installation

– removable insulation for transportation and installation

– numerous connectors for connecting large installations

– all connections on one side

– simple installation and maintenance, space saving with the possibility of wall mounting

– the possibility of using demineralized water or glycol

Reliability and convenience

– insulated structure maintains the parameters of the cycle

– collecting heat from several sources at the same time

– simultaneous operation with devices in open and closed systems

– selection of the optimal capacity, up to 2000 l

Even more benefits

-In tanks with a steel heat exchanger, it is possible to use solar energy for heating.

– can be connected to any type of fuel boiler, which facilitates the maintenance of the existing system, increases its efficiency.

The storage tank is the center of the heating system, which constantly supplies you with hot water and heat.

TECHNICAL DATA

| Type | um | ZB 200 | ZB 300 | ZB 500 | ZB 800 | ZB 1000 |

| Capacity | l | 200 | 310 | 475 | 752 | 921 |

| Type of insulation | – | PU foam* | styrofoam** | |||

| Maximum allowable temperature | °C | 95 | 95 | 95 | 95 | 95 |

| Minimum allowable temperature | °C | 6 | 6 | 6 | 6 | 6 |

| Maximum allowable pressure | bar | 3 | 3 | 3 | 3 | 3 |

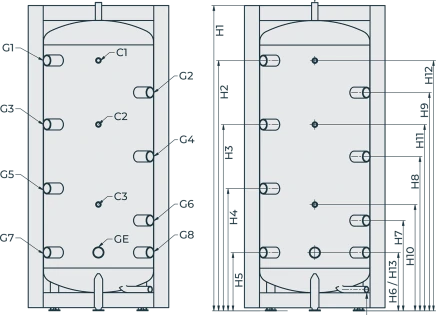

| H1 tank height | mm | 1250 | 1540 | 1940 | 1820 | 2140 |

| H2 Thermo Level | mm | 995 | 1230 | 1640 | 1500 | 1800 |

| H3 Thermo Level | mm | 755 | 910 | 1180 | 1110 | 1310 |

| H4 Thermo Level | mm | 515 | 590 | 730 | 720 | 820 |

| H5 Thermo Level | mm | 275 | 270 | 270 | 330 | 330 |

| H6 Thermo Level | mm | 275 | 270 | 270 | 330 | 330 |

| H7 Thermo Level | mm | 515 | 430 | 500 | 525 | 580 |

| H8 Thermo Level | mm | 755 | 750 | 950 | 915 | 1065 |

| H9 Thermo Level | mm | 955 | 1070 | 1400 | 1300 | 1555 |

| H10 sensor or thermometer Level | mm | 515 | 510 | 510 | 625 | 700 |

| H11 sensor or thermometer Level | mm | 755 | 910 | 1160 | 1110 | 1310 |

| H12 sensor or thermometer Level | mm | 955 | 1235 | 1640 | 1500 | 1800 |

| H13 electric heater connector Level | mm | 275 | 270 | 270 | 330 | 330 |

| Tank diameter (without insulation) | mm | 500 | 550 | 600 | 790 | 790 |

| Tank diameter (with insulation) | mm | 610 | 650 | 750 | 960 | 960 |

| Water supply/return diameter (Gw) | inch | 1 1/2 | 1 1/2 | 1 1/2 | 1 1/2 | 1 1/2 |

| Connection diameter for sensor or thermometer (Gw) | inch | 1 1/2 | 1 1/2 | 1 1/2 | 1 1/2 | 1 1/2 |

| Water drain diameter (Gw) | inch | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| Tank weight (without water) | kg | 40 | 60 | 80 | 90 | 130 |

* no possibility to remove the insulation

** it is possible to remove the insulation

Dimensions