Kamen Multi K5

Energy-saving, powerful boiler that is easy to operate. Wide power range. Extremely long life time and simple, minimal service

Advantages:

- We provide a guarantee for the boiler heat exchanger up to 6 years. *

- Simple operation.

- Convenient and easy boiler cleaning.

- Compact.

- The heat exchanger is made of 6 mm boiler steel.

- Reliable burner.

- Electronic protection against fuel tank ignition.

- Efficiency above 83%.

- Quiet fan operation.

- High fuel tank capacity.

- The fuel tank can be placed on the left or right side.

- The electronic controller ST-480 controls 4 circulation pumps (heating system, underfloor heating system, boiler, hot water and mixing valve actuator), a room temperature controller can be connected.

* there are additional conditions.

** free accessories

- outdoor temperature sensor

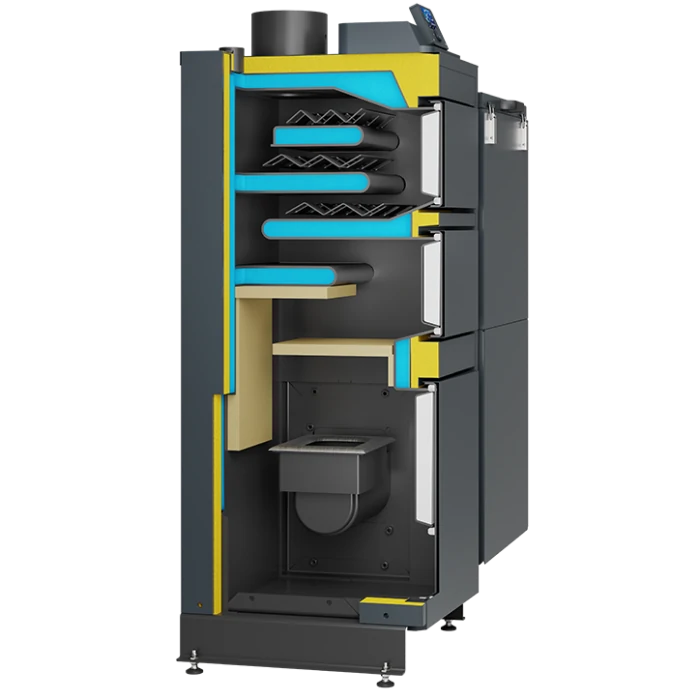

The pellet boiler Kamen MULTI K5 is one of the latest models from Kamen, which uses the latest technologies and components. The Kamen MULTI K5 boiler meets the highest eco requirements, has certificates of class 5 and ECODESIGN. The pellet boiler Kamen MULTI K5 is equipped with an automatic pellet feeding system with horizontal triple smoke intake, which allows you to burn crushed coal or wood pellets. Since the boiler uses modern solutions, the entire boiler service is refueling every 3-7 days and cleaning the convection channels. During the summer season, the boiler can only be used to prepare domestic water. In the Kamen Multi K5 boiler, the fuel tank can be on the right or left side. The boiler heat exchanger is made of 6 mm thick boiler steel 265GH, insulated with mineral wool and covered with powder coated steel sheet. Quality materials and structural elements used in the manufacture of the boiler ensure its durability and reliable operation. Boiler supply and return can be installed to the left or right of the boiler (optional).

Grid for solid fuel combustion chamber (option)

Technical details

| Model | 15 | 20 | 26 | 32 | ||||||

| Power | kW | 5 kW to 15 kW | 6 kW to 20 kW | 8 kW to 25 kW | 9 kW to 32 kW | |||||

| Heated surface | m2 | 1.8 | 2.4 | 2.9 | 3.5 | |||||

| Maximum width (A) | mm | 1090 | 1200 | 1200 | 1250 | |||||

| Width (A1) | mm | 475 | 545 | 545 | 615 | |||||

| Width with hopper (A2) | mm | 1090 | 1125 | 1125 | 1200 | |||||

| Maximum depth (B) | mm | 670 | 670 | 750 | 750 | |||||

| Depth (B1) | mm | 575 | 575 | 655 | 655 | |||||

| Chimney length (B2) | mm | 105 | 105 | 105 | 140 | |||||

| Maximum height (H) * | mm | 1415 | 1415 | 1415 | 1415 | |||||

| Boiler height (H1) * | mm | 1290 | 1290 | 1290 | 1290 | |||||

| Water supply head (H2) * | mm | 1310 | 1310 | 1310 | 1310 | |||||

| Height to chimney (H3) * | mm | 1395 | 1395 | 1395 | 1395 | |||||

| Chimney diameter (ØD) | mm | Ø158 | Ø178 | Ø178 | Ø178 | |||||

| Return water height (H4) * | mm | 345 | 345 | 345 | 345 | |||||

| Firebox capacity | kg | 180 | 180 | 180 | 180 | |||||

| Boiler weight | kg | 480 | 530 | 570 | 620 | |||||

| The amount of water in the boiler | L | 65 | 77 | 95 | 107 | |||||

| Boiler thermal efficiency | % | 89-92% | ||||||||

| Maximum pressure | bar | 1.8 | ||||||||

| Boiler water temperature (min./max.) | oC | 55/90 | ||||||||

| Source of power | V / Hz | 230/50 | ||||||||

| Chimney draft | Pa | 20 |

22 | 24 | 27 | |||||

| Minimum chimney height | m | 6 | 7 | 8 |

8 |

|||||

| Minimum parameters of the chimney | (Ømm) (cmxcm) |

Ø170 15 × 15 |

Ø190 17 × 17 |

Ø200 18 × 18 |

Ø220 20 × 20 |

|||||

| The area of the heated room | m2 | up to 150 | 150-120 | 200-260 | 250-320 | |||||

| Height adjustment from 24mm to 32mm (up to 40kW) * | ||||||||||

According to the manufacturer’s recommendations, boilers from 60 kW must be installed only in open heating systems !!!

Boiler dimensions